How to do LED lighting cooling effect of a good state

LED lamp cooling system design is related to the success or failure of the important part of the lamp, especially for high-power, high power density LED module, cooling problem is particularly prominent. If you can not LED module substrate temperature control in a reasonable range, lamp performance and life will be greatly reduced.

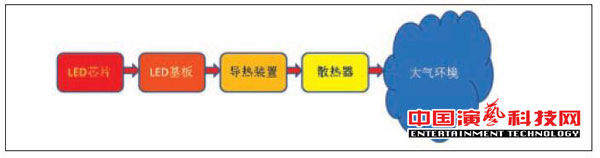

Figure 1 shows the LED lamp heat transfer path. It can be seen, LED chip heat (about 70% of LED power), will be through the LED substrate, thermal devices, heat sink to the atmosphere. Lighting designers can do that only try to reduce the thermal resistance of each link to reduce the temperature of the LED chip.

Figure 1 LED lamps heat transfer path

It should be noted that the thermal resistance of each link is a series relationship, must also reduce the thermal resistance of each link in order to reduce the system thermal resistance to a reasonable range. From the LED chip to the three parts of the radiator has a very good technical solutions, such as ceramic substrate, copper substrate, high thermal conductivity grease and heat pipe technology, you can heat down to a very small extent. But the last link, from the radiator to the atmospheric environment, but there is no perfect solution, only by strengthening the convection and increase the cooling area to achieve, which will bring lighting noise and lamp volume increases. There is a misunderstanding, and some manufacturers claim to use a high thermal conductivity of the new technology, you can cancel the fan, made in a small volume of high power LED lamps, through the above analysis we can see that this is contrary to the physical principles. No matter what the thermal conductivity technology, 70% of the lamp power to become heat from the light emerge out, the most effective way to heat or fan. To cancel the fan, you must greatly increase the heat dissipation area, surface area is not enough will lead to high temperature rise.

In fact, as long as the choice of excellent low-noise fan, reduce the speed of operation, can control the noise within the industry standard. LED lighting noise and computer shaking his head compared to the noise, can be ignored. Some news studios have a high demand for lighting noise control, and at this point, high-directional microphones can be used to prove that the production of such television programs is almost unaffected. Some manufacturers of fanless LED lamps to increase the power control device, when the LED light source temperature is too high will automatically reduce the LED power, then, the amount of light will be greatly reduced, which in the professional studio is not Accepted. The forthcoming cultural industry standard "LED stage lighting general technical conditions" provides: lamps in the normal use of the environment, requiring light output stability, the fluctuations should not be greater than 5%.

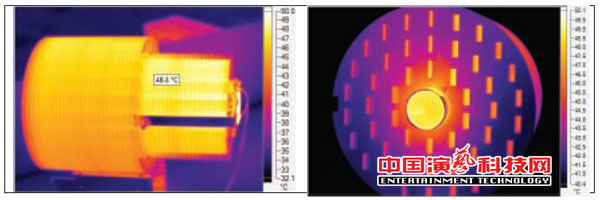

The only way to fanless LED lamps is to ensure adequate cooling area. In order to ensure that the LED module substrate temperature is controlled at 60 ℃ or so. Figure 2 shows the infrared test image of this lamp radiator.

Figure 2 100W fanless LED Spotlight Infrared test image